|

products |

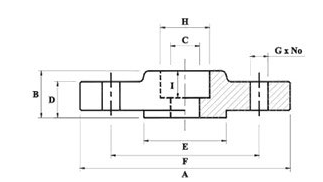

SOCKET WELDING |

|

Material Grade |

Gr1 Gr2 Gr3 Gr4 GR5 Gr7 Gr9 Gr11 |

|

Certification |

ISO9001:2008 Alibaba.com Assessed Supplier |

|

Standard |

ANSI B16.5 ASTM B16.5 ASME B16.47 JIS B2220 DIN2627-2628 |

|

size |

1/2"~ 60"NB NPS 1/2 - NPS 24 (DN 10 - 2000) |

|

Pressure Class |

PN0.25~32Mpa |

|

(DIN) PN6 PN10 PN16 PN25 though PN250 | |

|

150# 250# 300# 400# 500# 600# 900# 1500# 2500# | |

|

Technique |

Forged and CNC Machined |

|

type |

Weldnecks Slip-Ons Threaded Blind Socketweld and Lap-Joint |

|

Flange surface |

FF RF TG RJ MFM |

Socket welding flange, a popular type of pipe flange, was initially developed for use on small-sized high- pressure piping. The fabrication of this type of flange is similar to that of a slip-on flange. However, the internal pocket of a socket weld flange allows for a smooth bore and better fluid flow. When provided with an internal weld, the static strength of this flange is equal to slip-on flange, but the fatigue strength is 50% greater than double welding slip-on flanges. Smooth bore conditions in such a flange can easily be attained without having to bevel the flange face and, after welding, to re-face the socket weld flange as would be required with slip-on flanges. For this reason, the internally welded flange is popular in chemical process piping. The counter bore is sightly larger than the Outer Diameter of the matching pipe, allowing the pipe to be inserted. A restriction is built into the bottom of the bore, which acts as a shoulder for the pipe to rest on, and has the same I.D. of matching pipe. The flow is not restricted in any direction.