|

products |

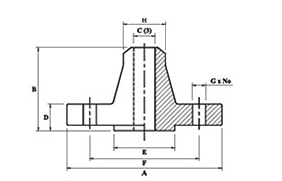

WELDING NECK FLANGES |

|

Material Grade |

Gr1 Gr2 Gr3 Gr4 GR5 Gr7 Gr9 Gr11 |

|

Certification |

ISO9001:2008 Alibaba.com Assessed Supplier |

|

Standard |

ANSI B16.5 ASTM B16.5 ASME B16.47 JIS B2220 DIN2627-2628 |

|

size |

1/2"~ 60"NB NPS 1/2 - NPS 24 (DN 10 - 2000) |

|

Pressure Class |

PN0.25~32Mpa |

|

(DIN) PN6 PN10 PN16 PN25 though PN250 | |

|

150# 250# 300# 400# 500# 600# 900# 1500# 2500# | |

|

Technique |

Forged and CNC Machined |

|

type |

Weldnecks Slip-Ons Threaded Blind Socketweld and Lap-Joint |

|

Flange surface |

FF RF TG RJ MFM |

WELDING NECK FLANGES are distinguished from other types by their long tapered hub and gentle transition of thickness in the region of the butt weld joining them to the pipe. The long tapered hub provides an important reinforcement of the flange proper from the standpoint of strength and resistance to dishing. The smooth transition from flange thickness to pipe wall thickness effected by the taper is extremely beneficial under conditions of repeated bending, caused by line expansion or other variable forces and produces an endurance strength of welding neck flanged assemblies equivalent to that of a butt welded joint between pipes, which, in practice, is the same as that of unwelded pipe. Thus this type of flange is preferred for every severe service condition, whether this results from high pressure or from sub-zero or elevated temperature, and whether loading conditions are substantially constant or fluctuate between wide limits.